Water Treatment Plant

General Equipment & Engineering is India’s leading fabricator/manufacturer and exporter of water treatment plants. We cover wide range of water treatment plants for water from different sources as Raw or Ground water, Waste water, Sewage water, Effluent water, Industrial Water

We undertake the work for Designing, Fabrication Erection, Commissioning and Annual Operation and Maintenance Contract of Water Filtration, Water Softener, RO (Reverse osmosis), waste water treatment, Effluent treatment (ETP), Sewage Treatment Plant (STP)

We offer wide range of filtration systems that enable treatment of suspended particles, color, odor & oil through filtration. The media filters involved filtration of particulates across surface & depth of media. Our filtration solution includes Gravity sand filter, Pressure sand filters, Dual media filters, Multimedia filters, Activated carbon filters, Walnut shell carbon filters, Micron filtration systems, Micro filtration systems

Membrane treatment processes is better solutions for increased levels of dissolved solids in water or water with high salinity, varying quality of water and wastewater. This process involves physical separation of suspended, colloidal, microbial, dissolved and selectively dissolved impurities through membranes. The membranes have varying pore sizes that are selectively used for treatment of water and works at certain pressure. We offer membrane systems of all capacities as Micro Filtration system, Ultra-filtration system, Nano-filtration system, Reverse Osmosis system, Sea water desalination systems

Our prime focuses are quality of product, on time delivery and customer satisfaction & have in house facility for fabrication and expertise in Design, manufacturing and quality. We rigorously check the products at each and every stage of manufacturing as per project requirement, national/ international code and standard.

Our water treatment plants are optimum quality, low capital and running cost, low maintenance cost, reliable, durable and user friendly. They are fully automatic, self contained and ready to install, low start up time. The plants are skid mounted and trailer made, can be operated through PLC and normal mode both.

We manufacture plant of different capacity and purity as per customer requirement and industry needs. Our offerings are:

- Drinking water Treatment Plant

- Water Filter Plant

- Water Softeners plant

- Ultra Filtration water Plant

- Reverse Osmosis (RO) Plant

- Desalination Plant

- Waste water Treatment Plant

- Effluent treatment Plant (ETP)

- Chemical treatment for Industrial Effluent

- Sewage Treatment Plant (STP)

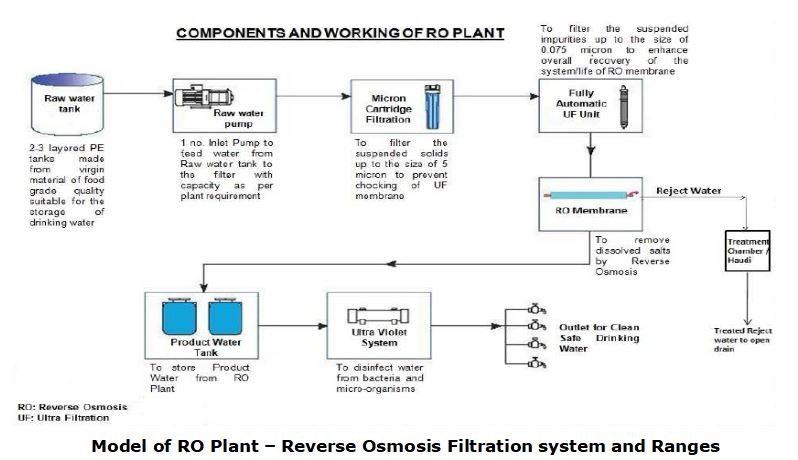

RO (Reverse Osmosis) Plant

General Equipment & Engineering is fabricator/manufacturer of RO plant for industrial and commercial use. RO is used in refinery, power plant, chemical plant, bottling plant, hotels, hospital, school etc. Our RO plant easily separate the eliminating microbiological impurities like bacteria and viruses, dissolved salts, chemicals, pesticides & Durable and Portable System. Our plant is Long life, Easy to handle suspended solids from water.

Raw water is stored in tank, Filtered in Micron and Ultra filtration unit, passes through RO membrane in view to remove dissolve salt by reverse osmosis.

MODEL | CAPACITY NM3/HR |

Gen-EE-RO-200 | 0 TO 200 LPH |

Gen-EE-RO-300 | 201 To 300 LPH |

Gen-EE-RO-500 | 301 TO 500 LPH |

Gen-EE-RO-1000 | 501 TO 1000 LPH |

Gen-EE-RO-1500 | 1001 TO 1500 LPH |

Gen-EE-RO-2000 | 1501 TO 2000 LPH |

Gen-EE-RO-3000 | 2001 to 3000 LPH |

Other sizes | As per requirement , Trailer made |

Sewage Treatment Plant (STP)

General Equipment & Engineering is fabricator/manufacturer of Sewage Treatment plant (STP) for industrial, commercial, Residential and Municipal use. STP is used in Municipal area, residential complex, hotels, hospital, school, hostel, refinery, power plant, chemical plant, bottling plant, etc.

Our STP easily separate the solid waste and impurities like suspended particle, bacteria and bacteria & our plants are durable, can be operated automatically and manual both, Portable and fixed both. Our plant is Long life, Easy to handle suspended solids from sewage water.

Sewage Water treated through different stages. It includes physical, biological and chemical processes to remove pollutants. Its aim is to produce environmentally safe sewage water, called effluent, and a solid waste, called sludge or biosolids, suitable for disposal or reuse. Reuse is often for agricultural purposes. Treated water used for farming, horticulture and houses

To make wastewater acceptable for reuse or for returning to the environment, the concentration of contaminants is reduced to a safe level, usually a standard set by the Environment Agency.

Conventional sewage water treatment involves either two or three stages, called primary, secondary and tertiary treatment. Treatment stages depending on quality expectation of treated water and use of water after treatment.

The proposed scheme above 03 stage treatment – Biological treatment (aerobic sewage treatment, settling stage to remove solid particle from water. chlorination and filtration stage ascertains that water acceptable to Environment norms.

Aerobic Sewage Treatment:

In this process, aerobic bacteria digest the pollutants. To establish an aerobic bacterial colony you must provide air for the bacteria to breathe. In a sewage treatment plant, air is continuously supplied by direct Surface Aeration using Impellers propelled by pumps which whisk the surface of the liquid with air, or by Submerged Diffused Aeration using blowers for air supply through bubble diffusers at the bottom of the tank. These achieve almost complete oxidation and digestion of organic matter and organic pollutants to Carbon Dioxide, Water and Nitrogen, thus eliminating the odour and pollution problem above. The effluent produced by this process is non-polluting and can be discharged to a watercourse

Settling:

Solid particle settle in tank and goes to filter pressure. Filter Press squeeze the liquid waste and convert sludge to solid and make dry.

Chlorination and Filtration:

Chlorination enhances water quality and filtration minimize suspended particle and control TDS. Softening and UV treatment may be added to enhance water quality.

Model of STP Plant – Sewage Treatment Plant and Ranges

MODEL | CAPACITY NM3/HR |

Gen-EE-STP-5 | 0 TO 5 KLD |

Gen-EE-STP-10 | 6 To 10 KLD |

Gen-EE-STP-20 | 11 TO 20 KLD |

Gen-EE-STP-30 | 21 TO 30 KLD |

Gen-EE-STP-50 | 31 TO 50 KLD |

Gen-EE-STP-100 | 51 TO 100 KLD |

Gen-EE-STP-150 | 101 to 150 KLD |

Other sizes | As per requirement , Trailer made |

Effluent Treatment Plant (ETP)

General Equipment & Engineering fabricator/manufacture of Effluent Treatment plant (ETP) for industrial, commercial, Residential and Municipal use. STP is used in Municipal area, residential complex, hotels, hospital, school, hostel, refinery, power plant, chemical plant, bottling plant, etc.

We offer Chemical Treatment technique in ETP as per industrial effluent, sometime biological treatment also adopted according to effluent. Design of ETP is completely depend on the Effluent characteristics like BOD, COD, TSS & ETC. The objectives in using chemicals and chemical reaction are to immobilize, mobilize for extraction, or detoxify the contaminants. The feasibility of chemical treatment is dependent on site and waste characteristics.

Model of ETP Plant – Effluent Treatment Plant and Ranges

MODEL | CAPACITY NM3/HR |

Gen-EE-ETP-5 | 0 TO 5 KLD |

Gen-EE-ETP-10 | 6 To 10 KLD |

Gen-EE-ETP-20 | 11 TO 20 KLD |

Gen-EE-ETP-30 | 21 TO 30 KLD |

Gen-EE-ETP-50 | 31 TO 50 KLD |

Gen-EE-ETP-100 | 51 TO 100 KLD |

Gen-EE-ETP-150 | 101 to 150 KLD |

Other sizes | As per requirement , Trailer made |